TL;DR (too long; didn’t read)

Beneath the town of Freiberg in Saxony exists a large underground mining system dating back to the 18th century. During construction work at the Untermarkt in 2018, the so-called family mineshaft (German: “Familienschacht”), which was used to mine silver, was rediscovered. Due to the visit of Alexander von Humboldt, the Familienschacht is also known as the Humboldt Shaft. For safety reasons, the mining system is not accessible to the public. However, a 3D model was created to enable visitors to experience it.

The mining industry in Freiberg

The Freiberg mining district is located in the north-eastern part of the Erzgebirge, which geologically extends further into the Czech Republic, where it is called Krušné hory. In the Freiberg mining district, as in other parts of the Eastern Erzgebirge, magmatic-hydrothermal ores were mined. These lie as skarn, greisen and epithermal vein deposits below an area of about 30×30 km (Swinkels et al., 2021). Such epithermal deposits are important sources of gold (13% of the world’ s production) and silver (∼17% of the world’s known resources) (Swinkels et al., 2021).

Geologically, the main part of the Freiberg mining area is located within biotite-plagioclase-orthogneiss and biotite-muscovite-paragneiss, which are present as an oval, dome-like structure surrounded by mica, phyllite, serpentinite-gabbro-amphibolite and gneisses (Swinkels et al., 2021). The eastern part of the area is dominated by Late Variscan Lower Bobritzsch biotite granite and the approximately ∼320 Ma old Tharandter Wald volcanic complex (Swinkels et al., 2021). Based on geochronological data, epithermal mineralisation occurred 276 ± 16 Ma ago (Ostendorf et al., 2019).

Active mining was carried out from the last third of the 12th century until the second half of the 20th century (Wagenbreth & Wächtler, 2015). The most important ores were galena, zinc blende, sulphur gravel, arsenic gravel, silver pale ore (freibergite), red galena ore and silver galena (Swinkels et al., 2021). Other mineral resources mined were quartz, calcite, barite and fluorspar (Wagenbreth & Wächtler, 2015).

The ore formations occur in certain combinations that can be assigned to a chronological order (according to Wagenbreth & Wächtler, 2015): Gravelly-blendeous galena formation (kb: arsenic gravel, sulphur gravel, zinc blende, silver-bearing galena, quartz), Noble brown spar formation (eb: Silver-bearing galena, sinber-bearing zinc blende, silver pale ore, red galena ore, silver galena and native silver and carbonaceous spar), Iron-Baryte Formation (eba: red iron ore, barite, quartz), Fluorobaryte Galena Formation (fba: Galena, sulphur pyrites, quartz, barite, fluorspar) and the Bismuth-Cobalt-Nickel-Silver Formation (BiCoNiAg, “Noble Fortunes”: Co-Ni arsenides, silver minerals, quartz, barite, carbonaceous spars). Kb and eb are from the Variscan orogeny (Upper Carboniferous to Permian), the eba and fba and BiCoNiAg are post-Variscan from Triassic to Cretaceous, possibly even Palaeogene / Neogene (Wagenbreth & Wächtler, 2015).

The mining centre was located in Freiberg, which gave this mining district the name “central district”. In addition to this central district with the mining regions of Himmelfahrt, Muldenhütten and Junge Hohe Birke, there were the mining regions of Kurprinz and Beihilfe (Halsbrücke district), Beschert Glück, Einigkeit, Vereinigt Feld and Himmelsfürst (Brand-Erbisdorf district). The latter was the most productive of all (Wagenbreth & Wächtler, 2015).

The first discoveries of silver were made in a field near Christiansdorf ( now Freiberg) in the 12th century. From 1168 to 1900, mining was carried out primarily for the extraction of silver (Swinkels et al., 2021). By 1874, 50,000 t of silver had been extracted from 344 mines (Wagenbreth & Wächtler, 2015). After an interruption, ores were again mined from 1933 to 1969 to extract lead, zinc, copper and tin (Swinkels et al., 2021).

The ores extracted from shallower, oxidised areas contain native silver (Swinkels et al., 2021). This is less common in the deeper zones. In the central district, silver is more likely to be present as a Galena mineral (galenite) or marginally as silver sulphides or sulphosalts (Wagenbreth & Wächtler, 2015; Swinkels et al., 2021). Often, there is also gold associated, which, however, has historically received less attention. The geoscientific collections of the TU Bergakademie Freiberg show a broad spectrum of extracted ores.

The history of the “Familienschacht”

The “Familienschacht” is one of the few shafts that were once dug within the city walls of Freiberg. This rather inconspicuous shaft, which is presumed to have been operated by hand winding, belonged to the “Neubeschert Glück in der Stadt” mine, a rather unknown mine (Wagenbreth, 1960). Its name has not been preserved either via names of shafts, hat houses or adit mouttholes from its golden years in the 18th century. Its history of just under one hundred years came to a swift end in 1799 with the end of underground mining.

It is remarkable that at the time when Alexander von Humboldt was studying in Freiberg (14.6.1791 to 26.2.1792), i.e. ten years before the end of mining, it was still in full bloom. The artificial equipment in the Wiesenschacht, which was one of the mine’s main shafts, was financed and brought up to the latest technical standard by a clever argumentation of Carl Gottlob Friedrich Goldberg, the supervisor of the mine since 1781, vis-à-vis the mining authorities. It was probably for this reason that Humboldt was first sent to this modern mine in the immediate vicinity of the city by his mentor, the mining academy inspector Gottlob Abraham Werner, a few days after his arrival in Freiberg (Wagenbreth, 1960).

Alexander von Humboldt’s excursion report of 5 July 1791 has been preserved. The description of the journey begins in the “Neubeschert Glück in der Stadt” mine at the Wiesenschacht and proceeds via various changes of level between the Eselstolln and Tiefer Fürsten-Stolln levels to the Familienschacht, where Humboldt ended his excursion (Wagenbreth, 1960). Whether it was intentional or a coincidence that Humboldt went out via the Familienschacht and thus found himself within sight of the Aschmarkt in front of the Freiersleben house, where his mentor and friend Johann Carl Freiersleben lived, remains open. In any case, it must have been a surprise for the latter.

Equally surprising was the encounter of the shaft head of the Familienschacht during the reconstruction and redesign of the Untermarkt in July 2018. This timing could hardly have been better – 2019 was the 250th anniversary year of Humboldt’s birth. Because of the link to this famous personality, the mineshaft is now also fondly referred to as the Humboldt Shaft. For safety reasons, the Familienschacht is not open to the public and was therefore digitised and documented on film by the TU Bergakademie Freiberg and the Saxonia-Freiberg-Stiftung in the form of a 3D model. The data for this 3D model was captured using a handheld laser scanner (see below). In addition to a specially designed manhole cover at the top of the shaft, there is a stele at the same location and screens in a display window for the presentation of video material from the shaft and tunnel system.

Methods – Use of the handheld laser scanner

The ZEB-REVO is a hand-held measuring unit consisting of a rotating laser scanner and an inertial measurement unit (IMU). The system is designed to be manually guided through space by the person measuring. The laser head rotates at a speed of 0.5 Hz, so that in combination with the movement of the person measuring, the system constantly changes its spatial position. With a maximum range of 30 m, the ZEB-REVO is suitable for recording indoor spaces. The laser unit is capable of capturing 43,200 points per second. Its detection field is 360° x 270°. When the hand-held scanner is held upright, the resolution is 1.8° vertically and 0.625° horizontally. The laser class 1 enables eye-safe working. If the RT (Real Time) version is not used, the ZEB-REVO is certified in protection class IP64. The ZEB-REVO weighs one kg and is connected via a cable to the registration and battery unit, which can be comfortably carried on the shoulder (fig. 1). At www.geoslam.com (2021) the technical parameters are listed.

The processing of the immense amounts of raw data generated by the scanning process and the operation of the necessary software require good hardware and corresponding know-how (for further information, see (Hößelbarth et al., 2018; Martienßen & Wandinger, 2019). The innovation in the “Familienschacht” application case is the use of such a scanner in a tilted shaft in unassisted movement. For this purpose, the measuring system was attached to the bucket of the material rope drive with the help of an auxiliary construction (Fig. 2). The measuring process took place in slow travel through the shaft over a depth of approx. 35 m and lasted approx. 8 minutes in the raising and lowering of the bucket.

The aim of using the ZEB-REVO in the Familienschacht was, on the one hand, to test it under practical conditions and, on the other hand, to use it for the determination of classic mine surveying. The aim was to eliminate the need for small-scale surveying on site and to carry out the work of recording the joint edges from the point clouds in the office (see also video contribution). The mine surveying work on site would be limited to the tachymeter measurements. The advantage of using the point clouds in the follow-up is seen in the fact that the situation does not have to be interpreted immediately on site and that the first step is a complete detection of the excavation voids within the range of the hand-held scanner. The interpretation of the local situation and the digitisation of the joint edges is the second step and takes place afterwards in the office. Here, the evaluating person can view the point cloud from the different perspectives using 3D software and make measurements. This also reduces the time spent on site, which can also be important for safety reasons. Whether this new way of working can be an alternative to the conventional procedure is to be assessed by the in-field service partner within the scope of the investigations.

The accuracy of the measurement method has already been investigated in Martienßen & Wandinger (2019) and can be regarded as sufficient for a survey, following the guidelines for measurement value acquisition formulated in Martienßen & Wandinger (2019). The use of control points is recommended in any case if accuracies in the centimetre range are to be achieved.

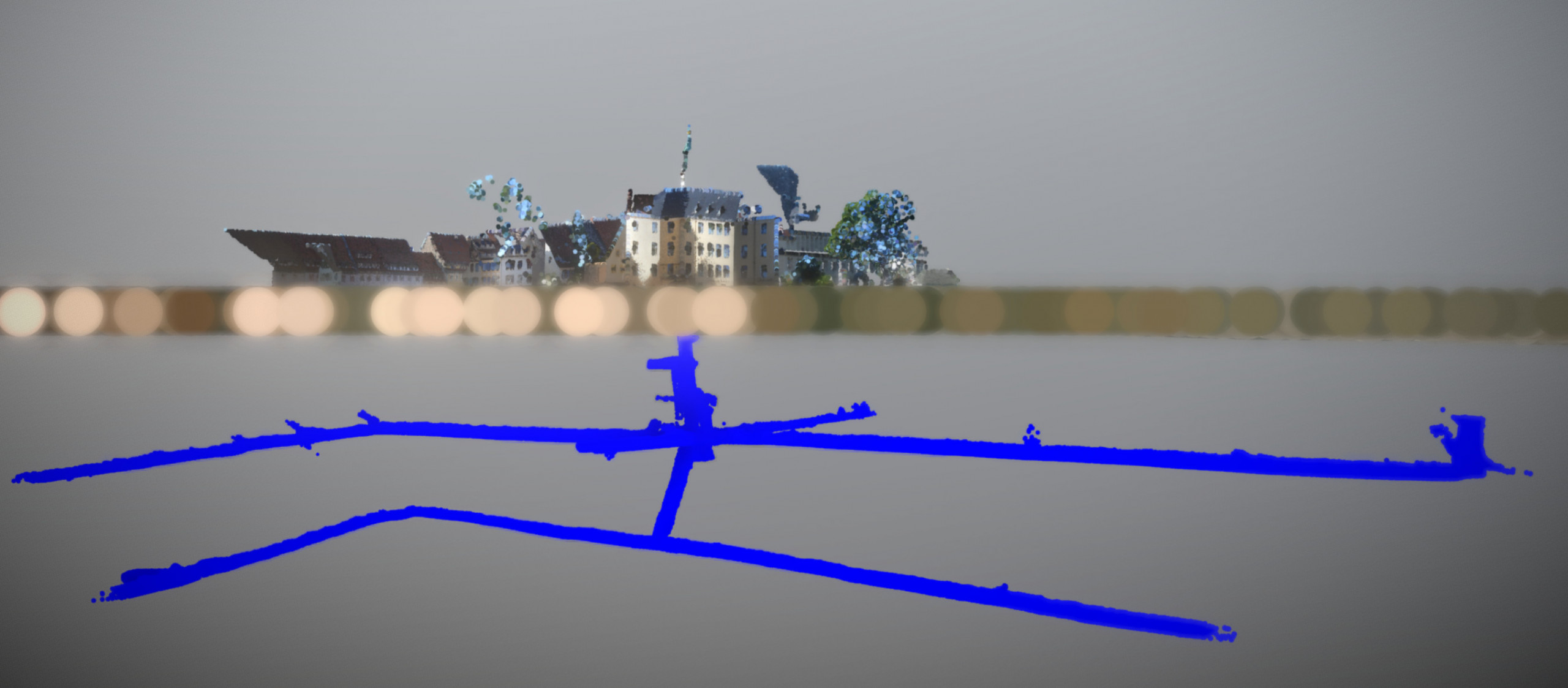

3D model

References

Hößelbarth, D., Richter, O., Martin, C., Martienßen, T. & Wandinger, M. (2018): Erste Erfahrungen mit dem handgeführten Laserscanner ZEB-REVO bei Vermessungsarbeiten im Altbergbau am Südtiroler Schneeberg; Tagungsband 18. Altbergbau-Kolloquium 2018 (08.-10.11.2018), 221-234.

Martienßen, T. & Wandinger, M. (2019): Anwendung des handgeführten Laserscanners ZEB-REVO im Bergbau; Tagungsband 18. Oldenburger 3D Tage 2019 (06.-07.02.2019), 2-11.

Ostendorf, J., Henjes-Kunst, F., Seifert, T., & Gutzmer, J. (2019): Age and genesis of polymetallic veins in the Freiberg district, Erzgebirge, Germany: constraints from radiogenic isotopes. Mineralium Deposita, 54(2), 217-236.

Swinkels, L.J., Burisch, M., Rossberg, C.M., Oelze, M., Gutzmer, J. & Frenzel, M. (2021): Gold and silver deportment in sulfide ores – A case study of the Freiberg epithermal Ag-Pb-Zn district, Germany. Minerals Engineering (174).

Wagenbreth, O. (1960): Alexander von Humboldts Grubenfahrt auf „Neubeschert-Glück in der Stadt“ und die Geschichte dieser Freiberger Grube; Freiberger Forschungsheft D33; Akademie-Verlag, Berlin, 151-166.

Wagenbreth, O., & Wächtler, E. (Eds.). (2015): Der Freiberger Bergbau: Technische Denkmale und Geschichte. Springer-Verlag.

www.geoslam.com (2021), angerufen am 10.11.2021 unter https://geoslam.com/solutions/zeb-go.